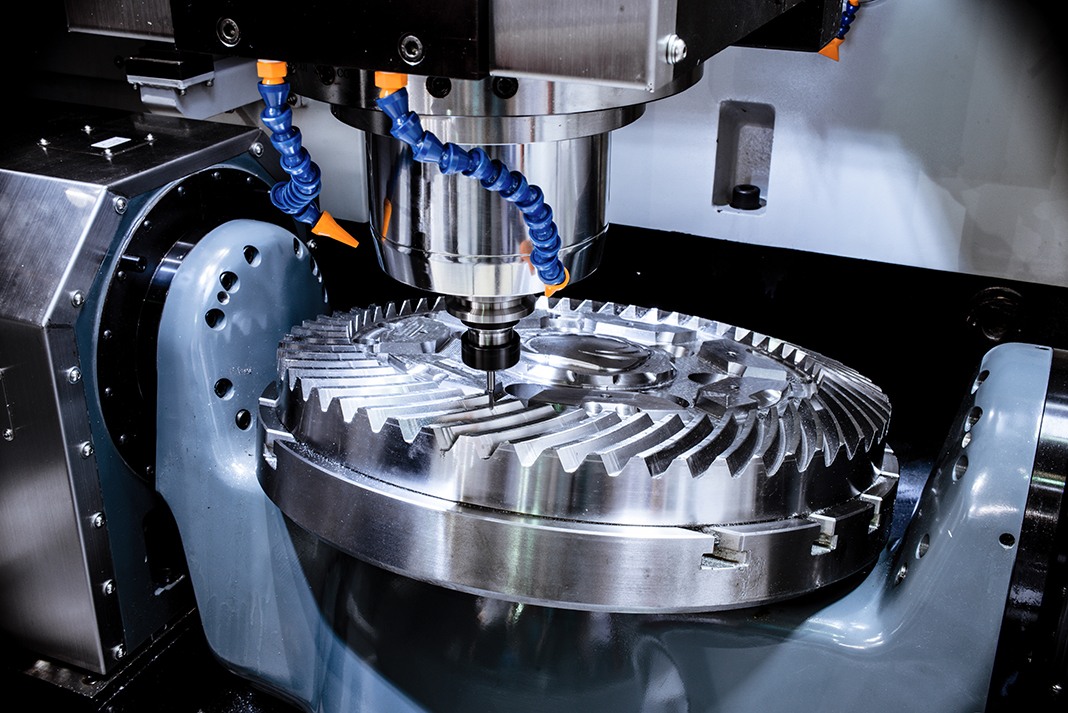

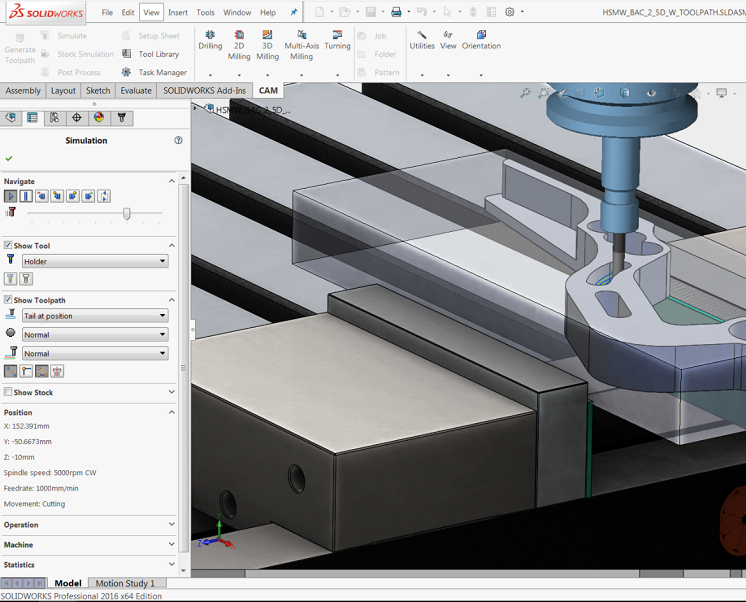

CNC MILLING

CNC milling service we provide on several new generation machining centers, the degree of complexity, and the class of precision is determined by the client. We are able to produce parts of almost all materials - aluminum, steel, copper, brass, stainless steel, plastic...

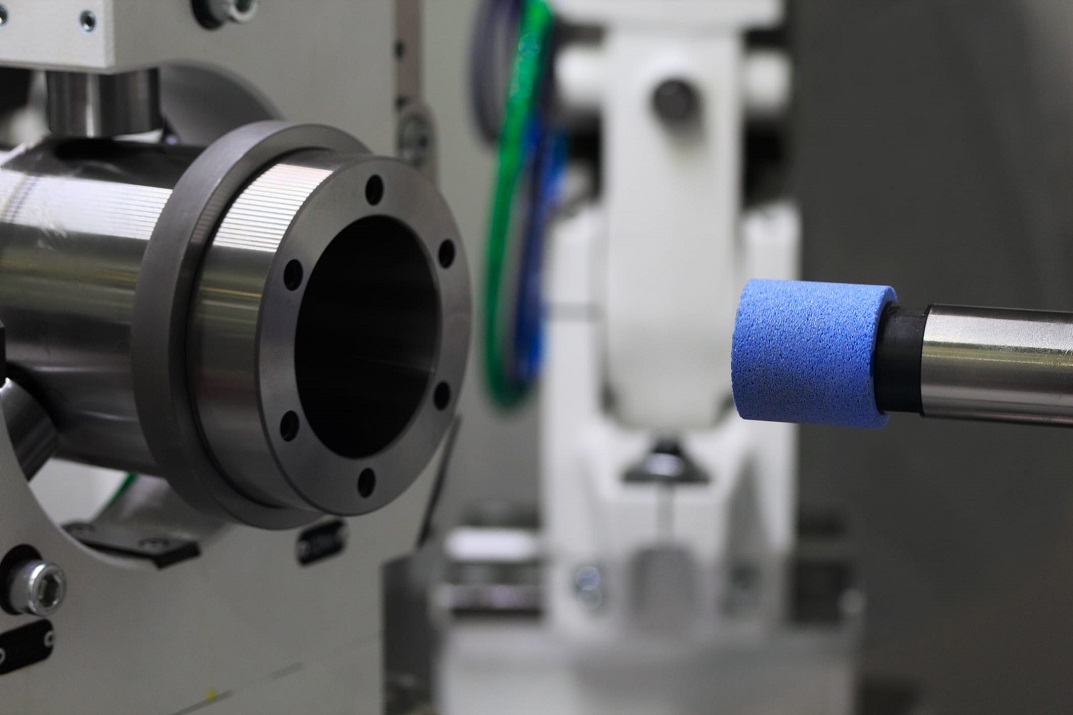

CNC TURNING

The service we provide on the CNC turning machine OKUMA LC10 2ST. The machine has two heads each with 8 tools and automatic feeding. Materials can be up to 300mm, and diameter of 42mm.

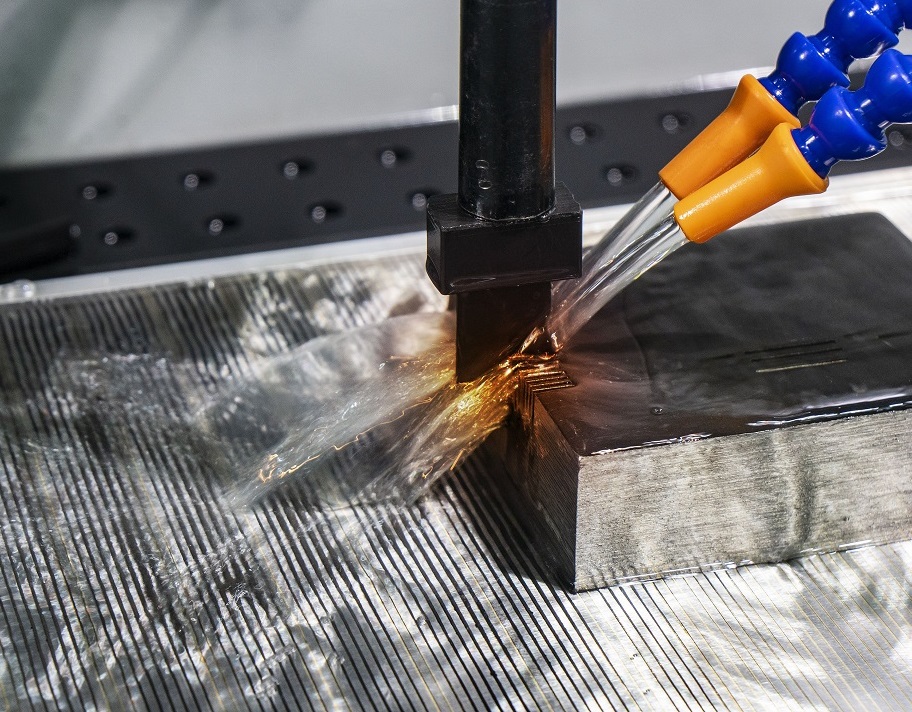

EDM

Erosion is a method that is usually used when processing a very hard metal, when the usual methods are not effective. Eroding can get the desired contours and shapes of the hardest metals without softening process heating.

Services eroding perform the machine SIEGBURG RHEINLAND that German manufacturing and a 3 - axis.

With this machine, we are also able to take out all you can break in the material like drills, taps, end mills, etc.

ANODIZING ALUMINUM

Anodizing (electrolytic oxidization) is the process of using electrical current to the cases of aluminum and its alloys produced by the layer of aluminum oxide. Anodized layer protects the object from corrosion and wear, serves as electrical and thermal insulator, and can serve as a base for spreading protective paints and varnishes.

The process of anodization comprises:

- Mechanical brushing prepares profiles, devices with circular brushes of thin stainless steel wire

- Degreasing in detergents at a temperature of from 65 to 75 ° C for 10 minutes

- Degreasing in mineral drums (sodium hydroxide) at a temperature of 40 to 60 ° C for 5 minutes

- Neutralization of the nitric acid

- Anodising in sulfuric acid at a temperature of 18 ° C for 50 minutes

- Coloring (if required other hue)

- Closing the pores or alloying (cold and hot), about 3 minutes.

In addition to the standard aluminum anodizing services, we can deliver the service hard anodization. Also, in cooperation with our company you can obtain the highest quality paint for anodizing.

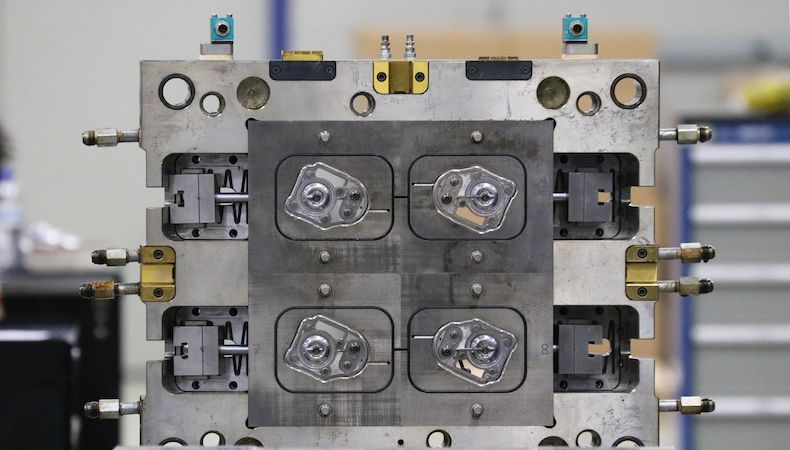

MAKING TOOLS

Based on your requirements and design documentation we can make development tools for different purposes.

Production capacity, knowledge and our experience guarantees quality tools, regardless of the degree of complexity and accuracy class that you define.

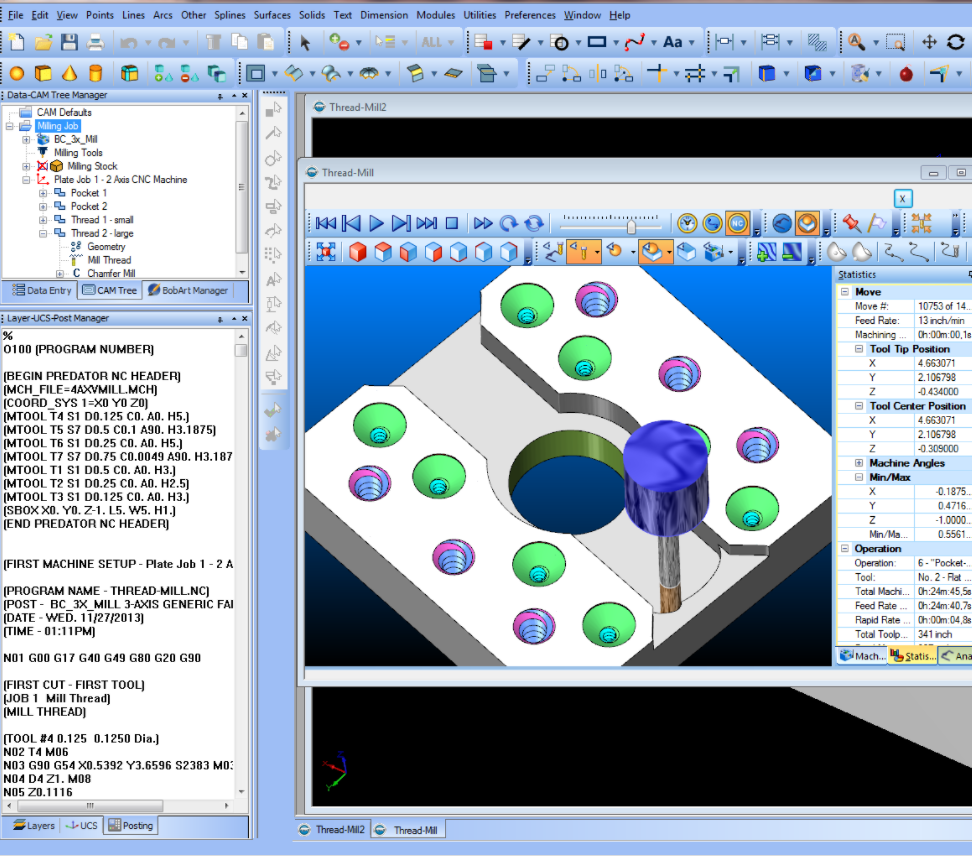

CNC PROGRAMMING

Service programming for CNC lathes and machining centers are performed by experienced developers who will provide you with optimal resource utilization and maximum productivity.

We are able to provides technology training for cnc developers and operators on the machines for our partners who have their own equipment and machines. We are able to educate them completely and help them to start serial production.

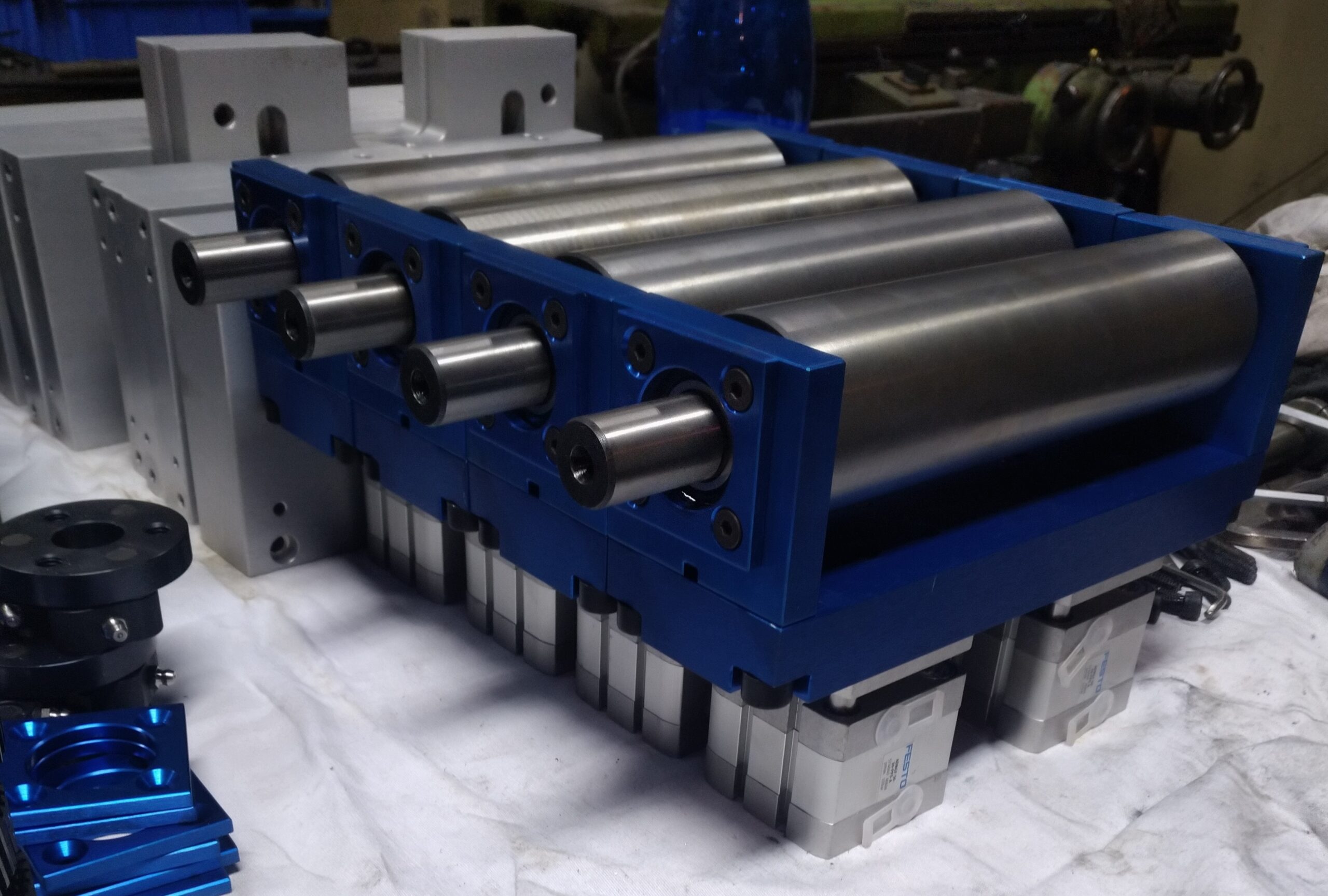

MOUNTING ASSEMBLIES

For the needs of our clients, we also offer mounting assemblies.

In addition to the parts that are produced in our plants, assemblies usually include various other parts. Purchase of additional parts and their assembly is done in consultation with the client.

In this way, our customers reduce the cost and time required to produce the final product.

PROJECTING

The service project development involves finding the optimum conceptual design, technology development, definition of materials, tools, sequence of operations and modes. On the basis of the project and project documentation access to the process of writing programs for CNC machines.

Projecting and development of technical documentation carried out by trained personnel whose theoretical and practical knowledge confirmed by a large number of real projects.

Experience guarantee a successful and practical solutions, detailed and clear technical documentation.

We are able to provides technology training for cnc developers and operators on the machines for our partners who have their own equipment and machines. We are able to educate them completely and help them to start serial production.

QUALITY CONTROL

The process of quality control in the company MAL & Industry KO is on the first place. Continuous and thorough control of each workpiece repeatedly guarantees the best quality of our services. Precision-built parts and control in our company is up to 0,005 mm.

Devices on which we perform quality control are:

1. Tesa Micro-Hite 3D

2. Tool Master Okta 2

3. Trimos “Vertical 3” Measuring System

4. "Mitutoyo" measuring instruments

5. "Kreplin" measuring instruments

6. Other gauges superior quality

CUTTING AND POLISHING

For the needs of our clients, we also offer material cutting and polishing. We are able to cut all kinds of materials.

We possess automatic band saws brand "FORTE" and saw a new generation brand "RAMSAUER AL 500 ANC" on which we very precise cutting material.

VENEER BRIQUETTING

We are able to briquette veneer created in the production process in order to reduce the size and easier transport of veneer. In this way, we maximize the utilization of raw materials. We briquette veneer of any material.

WATER JET

Water jet cutting service. Possibility of cutting all types of materials from 0.5mm to 300mm thick. Pressure 6200 bar.

Contact information

Address:

Mose Pijade 16, Jarak, Sremska Mitrovica

Email:

branislavkozenko@gmail.com

Phone:

+381 64 144 69 55

Business data

Business name:

Kozenko Company d.o.o.

Company number: 21709182

Tax ID: 112627543

Activity code: 2562 - metal machining

Main activities

Making custom parts. cnc milling, cnc turning, eroding, anodizing of aluminum, quality control, cnc programming, design and production of technical documentation, ...